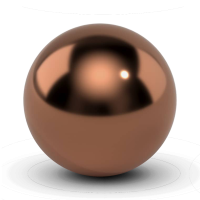

Chrome Steel Balls

Chrome steel balls, also known as bearing balls or chrome steel bearing balls, are precision-engineered spheres made from high-quality chrome steel alloy. These balls are commonly used in bearings, valves, and other mechanical components where smooth, low-friction movement is crucial. The chrome steel alloy provides excellent hardness, wear resistance, and corrosion resistance, making these balls durable and long-lasting. They are manufactured with tight tolerances to ensure consistent performance and reliability in various industrial applications. Chrome steel balls are available in a range of sizes and grades to suit different requirements, from miniature precision bearings to heavy-duty industrial machinery.